Research conducted in this area encompasses design and optimization of bioprocesses, mathematical modelling for bioprocess optimization, microalgae cultivation for bioproduct synthesis, biofuels and biorefinery processes. Some of the specific research activities include microalgae-based astaxanthin production, design of photobioreactors for microalgae cultivation under local climatic conditions, development of strategies for valorization of residual biomass in a biorefinery context, process development for pre-treatment of microalgae biomass, biological carbon dioxide sequestration, biological treatment of industrial wastewater, biochemical conversion of rice straw, biofuel production, characterization of biowaste catalyst and non-thermal plasma sterilization

Team:

- Prof. A.A.P. de Alwis

- Prof. (Mrs) Sanja Gunawardena

- Dr. Thilini U. Ariyadasa

- Dr. Thushara Subasinghe

- Dr. Mahinsasa Rathnayake

- Dr. Tharushi Keerthisinghe

- Dr. Poorna Vidanage

Our Research Cases:

Microalgae-based bioremediation of wastewater and flue gas

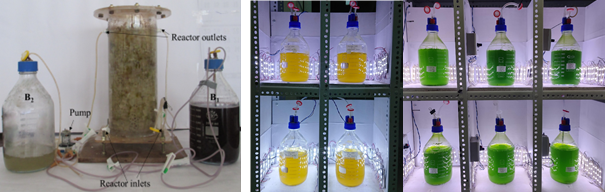

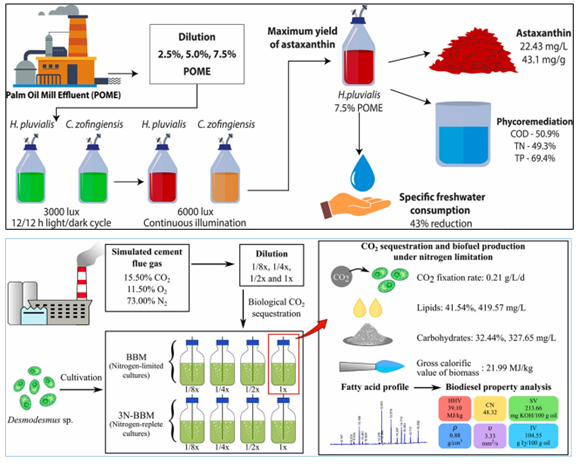

The aim of this study, supervised by Dr. Thilini U. Ariyadasa, was to utilize microalgae for bioremediation applications such as treatment of industrial wastewater and carbon capture from flue gas streams. The advantage of using microalgae for bioremediation applications is that it concurrently and sustainably produces valuable biomass which can be utilized for synthesis of high-value bioproducts and biofuels. The research team collaborated with partners from the local industry and developed bioprocesses using the microalga Haematococcus pluvialis and Desmodesmus sp. for effective treatment of palm oil mill effluent (POME) and generation of biomass which can be utilized for astaxanthin production, as well as sequestration of CO2 from simulated cement flue gas while generating biomass which can be utilized for biofuel production

More information:

Dr. Thilini U. Ariyadasa

Cultivation of microalgae in palm oil mill effluent (POME) for astaxanthin production and simultaneous phycoremediation (2021), Journal of Environmental Chemical Engineering, 9(4), 105375. https://doi.org/10.1016/j.jece.2021.105375

Nitrogen-limited cultivation of locally isolated Desmodesmus sp. for sequestration of CO2 from simulated cement flue gas and generation of feedstock for biofuel production (2021), Journal of Environmental Chemical Engineering, 9(4), 105765. https://doi.org/10.1016/j.jece.2021.105765

Co-production of high-value products and biofuels from the marine microalga Tisochrysis lutea

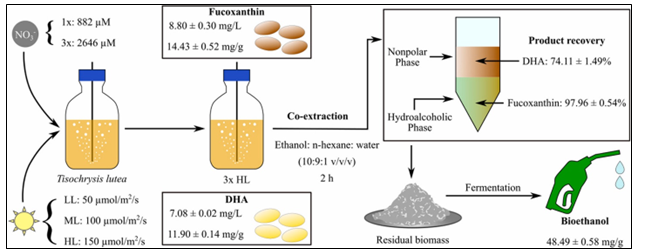

This study aimed to utilize a biorefinery approach to co-produce the high-value compounds fucoxanthin and docosahexaenoic acid (DHA) from the marine microalga Tisochrysis lutea for nutraceutical and pharmaceutical applications. The incident light intensity and nutrients in the culture media were varied to maximize the co-synthesis of fucoxanthin and DHA. Thereafter, a novel biphasic solvent system was utilized for extraction and fractionation of fucoxanthin and DHA, which allowed the recovery of ~98% of fucoxanthin and ~74% of DHA. The fermentation of the residual biomass obtained after product extraction resulted in a yield bioethanol ~48 mg/g, confirming the suitability of T. lutea as a feedstock for multiproduct biorefineries. This study was an outcome a collaborative project between DCPE, UOM and Prof. Anushree Malik from the Indian Institute of Technology Delhi (IITD), New Delhi, India under the Indo-Lanka joint research programme.

More information:

Dr. Thilini U. Ariyadasa

Co-production of fucoxanthin, docosahexaenoic acid (DHA) and bioethanol from the marine microalga Tisochrysis lutea (2021), Biochemical Engineering Journal, 176, 108160. https://doi.org/10.1016/j.bej.2021.108160

Synthesis of astaxanthin in Haematococcus pluvialis via manipulation of phosphate supply and induction of continuous light stress

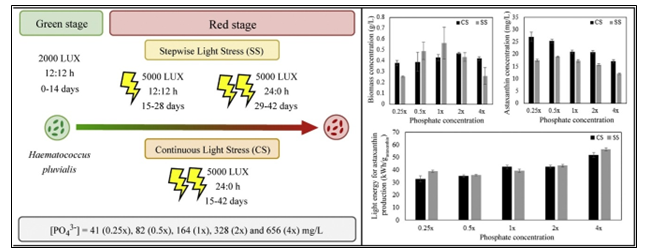

This study aimed to investigate the effect of the initial phosphate concentration in the culture media and the light stress regime on astaxanthin accumulation in the microalga Haematococcus pluvialis. The enhancement of astaxanthin yield is desired as it is a high-value antioxidant compound used in nutraceutical and pharmaceutical applications. Accordingly, several combinations of initial phosphate concentrations and stepwise/continuous light stress were provided to H. pluvialis cultures. The highest astaxanthin concentration in the culture broth and lowest specific light energy consumption for astaxanthin synthesis were reported in cultures grown in 41 mg/L phosphate under continuous light stress. The maximum reported astaxanthin content in H. pluvialis reached 7% on dry weight basis. This study was an outcome a collaborative project between DCPE, UOM and Prof. Anushree Malik from the Indian Institute of Technology Delhi (IITD), New Delhi, India under the Indo-Lanka joint research programme.

More information:

Astaxanthin accumulation in the green microalga Haematococcus pluvialis: Effect of initial phosphate concentration and stepwise/continuous light stress (2020), Biotechnology Reports, 28, e00538. https://doi.org/10.1016/j.btre.2020.e00538