Pilot plant laboratory bridges theory and practice, offering hands-on experience for students and researchers in chemical and process engineering. It provides scaled-up equipment, real-world process insights, and collaboration with industries, fostering practical skills and interdisciplinary innovation. Unit operations, recognized as the heart of this field, are central to the laboratory's focus.

Major Equipment and Facilities in the Laboratory

Apparatus for determination of Heat loss from Bare and Lagged Pipes

Equipped with a bare pipe and three pipes lagged with Chromium, Fibre Cast and Rockwool, this apparatus is used in determining the outside and inside heat transfer coefficients of circular pipes. When operating, steam is allowed to flow into the pipes and the heat loss through pipes is calculated by obtaining the condensate volume collected through steam traps. Thermocouples and pressure gauges attached to the apparatus are used in obtaining temperature and pressure readings, respectively.

Multi-effect Evaporator

Multi-effect evaporator apparatus is used to determine the performance of double-effect evaporation along with the calculation of steam economy. In this apparatus, the steam generated in one effect is used as the source of heat for the subsequent evaporator resulting in a significant reduction in steam consumption for the evaporation process.

Continuous Crystallizing System

The continuous crystallizing apparatus consists of a crystallizer and a centrifuge. The crystallizer is used to initiate the crystallization process giving a supersaturated solution as the output. This solution is then introduced to the centrifuge to separate crystallized particles from the mother liquid

Filter Press Apparatus

This pilot scale filter press facilitates conducting constant pressure filtration tests to determine filter cake resistance and filter medium resistance. This apparatus consists of a feed tank, a centrifugal pump and a filter press

Boiler

The boiler available in the lab satisfies the steam requirement of laboratory experiments in the Department of Chemical and Process Engineering. This diesel-fired water tube boiler has the capacity to deliver steam at a rate of 250 kg/hr with an operating pressure of 7.5 bar.

Centrifugal Separator

This Centrifugal separator is used to demonstrate the separation process of a suspension consisting of two or more phases of different densities by using the centrifugal force. The fields of application of this technique range from chemical and pharmaceutical industries through oil and fat recovery to the production of dairy products, wine, and beer, as well as the processing of mineral oil.

Reverse flow Cyclone separator

The application of this apparatus is to demonstrate the removal of entrained particles from a gas stream. Here, gas enters the top of the separator body, flows downwards, then flows back upwards followed by discharge from the top

Apparatus for Retort processing

This apparatus is used to demonstrate the food processing method that uses heat and pressure to commercially sterilize food after it has been placed and sealed in its containers. The high temperatures and pressures allow the sterilization process to complete in a shorter time reducing the time that the products need to be exposed to heat.

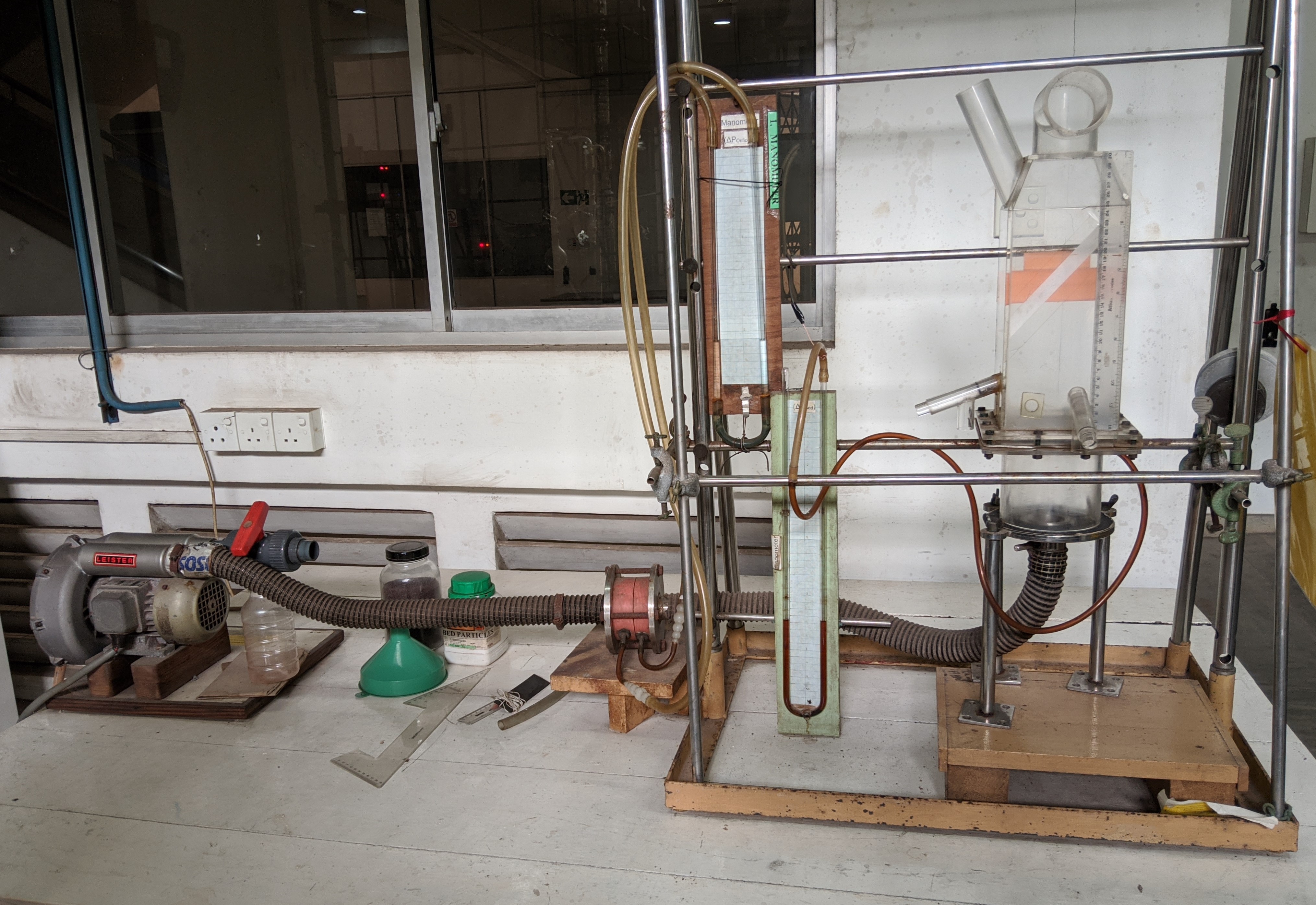

Packed Bed and Fluidized Bed Chamber

This apparatus consists of a chamber fixed into a blower where the blower forces air through the chamber to create a fluidized bed. This can be used in determining the relationship between pressure drop and superficial velocity for a packed bed. This can also be used to calculate the minimum fluidization velocity required for fluidization.

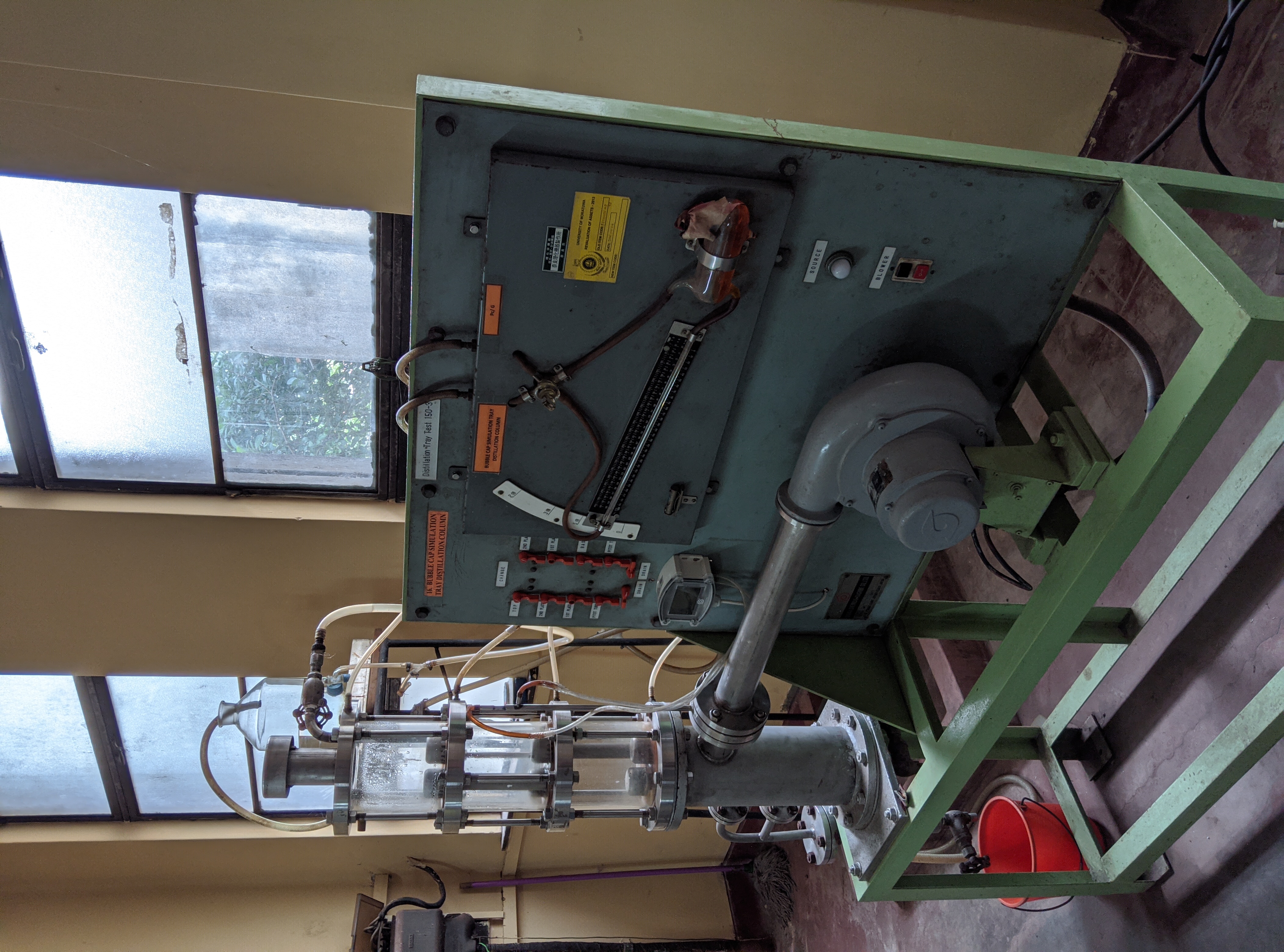

Bubble Cap - Simulation tray

This apparatus is used to analyze the effects of variations of vapour and liquid flow on the pressure drop across bubble cap plates by simulating the operation of a distillation column. Here, air and water are used to represent the vapour and liquid respectively

Distillation Column

This pilot scale distillation column available at the lab allows students to demonstrate the working principle of an actual distillation column used in many industrial practices. Equipped with temperature and pressure gauges at various stages, this apparatus can deliver the required parameters to analyze the process of distillation at each stage.

Major Practical Experiments Conducted in the Laboratory

CH 2270 Laboratory Practice II (Semester 4)

- Pressure Drop in a Packed Bed, Fluidized Bed and Over a Bubble Cap Plate

- Filter Press

- Demonstration on Cyclone, Centrifuge and Sieve Analysis

- H.E.T.P. Distillation

- Soxhlet Extraction

- Evaporation

Available Testing Services

Pilot plant equipment can be made available for outside services on request, if appropriate. In addition, the boiler is available for relevant services under the supervision of an experienced boiler operator.

Laboratory Staff / Contact us

Lab-in-charge: Dr. Duleeka Gunarathne (duleekas@uom.lk)

Technical Officer: Mr. B.H.P. Mahendra (padmalalm@uom.lk)

Boiler Operator: Mr. BARD Abeywardana

Lab Attendant: Mr. Viranga Somarathna